- Home

- >

- Products

- >

- Muffle Furnace

- >

- 2002 Muffle Furnace

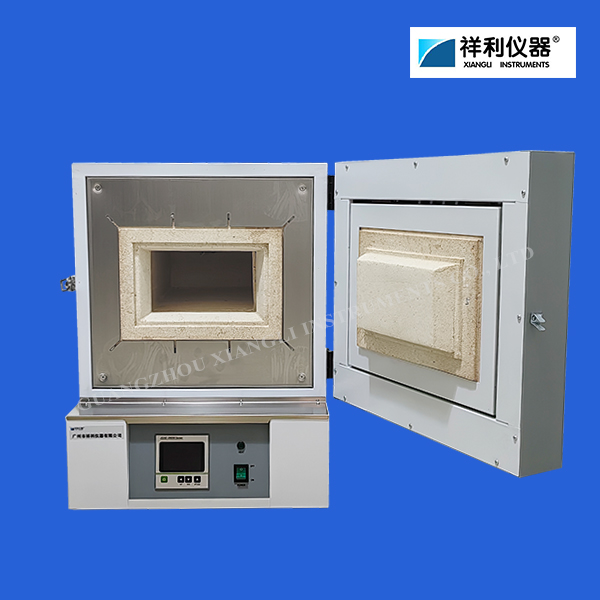

2002 Muffle Furnace

Brand :XIANGLI

Product origin :China

Delivery time :10 days

Supply capacity :1000

Muffle furnace can determine the content of inorganic fillers.

Muffle furnace ash test testing oven is used to do some elemental analysis, physical measurement, raw materials burning, small work hardening, and annealing, tempering and other heat treatment.

Product parameter

★ Type: MFL-2002

★ Max temperature: 1000℃

★ Inner size: W*D*H 300*200*120mm

★ Heating part: resistance wire spiral

★ Volume: 7L

★ Max power: 4KW

★ K type heating time: less than 20 min

★ Suitable type heating time: less than 60 min

★ Working voltage: 220V

Application

★ Ash test testing oven is widely used in various tertiary institutions, industrial and mining enterprises and scientific research units, laboratories and laboratories.

★ It is used to do some elemental analysis, physical measurement, raw materials burning, small work hardening, and annealing, tempering and other heat treatment.

★ Ash test testing oven can be use for sintering, dissolving and analyzing the metal and ceramic.

★ The effect of the muffle furnace on plastics is mainly high-temperature decomposition. The plastic sample is completely burned in the muffle furnace (above 600°C), and the content of inorganic fillers can be determined.

★ The specific behavior varies depending on the type of plastic and conditions (temperature, atmosphere):

- PE (polyethylene): decomposes at about 300-400°C, and degrades into wax and gas after melting.

- PP (polypropylene): similar to PE, but the decomposition temperature is slightly higher (about 400°C).

- PVC (polyvinyl chloride): releases hydrogen chloride (corrosive gas) at 200-300°C, which needs to be handled with caution.

- PET (polyester): decomposes at about 350°C, producing benzene and carboxylic acid.

- PS (polystyrene): liquefies at high temperatures and releases styrene monomer (toxic).

- Engineering plastics (such as PC, nylon): have high temperature resistance (some can reach 200-300°C), but will still decompose if the limit is exceeded.

Maintain

1. Open the machines everyday periodically.

2. Operated by the specialist.

3. Ash test testing oven and accessories must be deposit in the dry environment.

4. After testing the accessories should be added wiping grease rust, and remove the rust great before test.

5. When the test finished, the power should be closed to avoid any accident.

Certificate