- Home

- >

- Products

- >

- Muffle Furnace

- >

- Muffle Furnace for Ash Determination

Muffle Furnace for Ash Determination

Brand :XIANGLI

Product origin :China

Delivery time :10 days

Supply capacity :1000

The effect of the muffle furnace on plastics is mainly high-temperature decomposition. The plastic sample is completely burned in the muffle furnace (above 600°C), and the content of inorganic fillers can be determined.

Advantages of Muffle Furnace

★☆The muffle furnace produced by our company is widely used in laboratories and laboratories of plastic processing, colleges and universities, industrial and

mining enterprises, and scientific research institutions. It is used for element analysis, physical measurement, raw material roasting, quenching, annealing,

tempering and other heat treatment of small workpieces. It can also be used for high-temperature heating such as sintering, dissolving, and analysis of

metals and ceramics.

★☆The effect of the muffle furnace on plastics is mainly high-temperature decomposition. The plastic sample is completely burned in the muffle furnace (above

600°C), and the content of inorganic fillers can be determined.

★☆This equipment can intelligently control time and temperature in sections, and meets the standards of ISO 3451-1:1997, "GB/T9345.1-2008 Plastics

Determination of Ash Content Part 1 General Method".

Product features of Muffle Furnace

Made of high-quality steel plate

Ash content determination muffle furnace box-type resistance furnace adopts domestic advanced technology. The furnace shell is made of high-quality steel plate by folding welding, and the control box and the furnace body are an integrated structure.

Appearance is beautiful

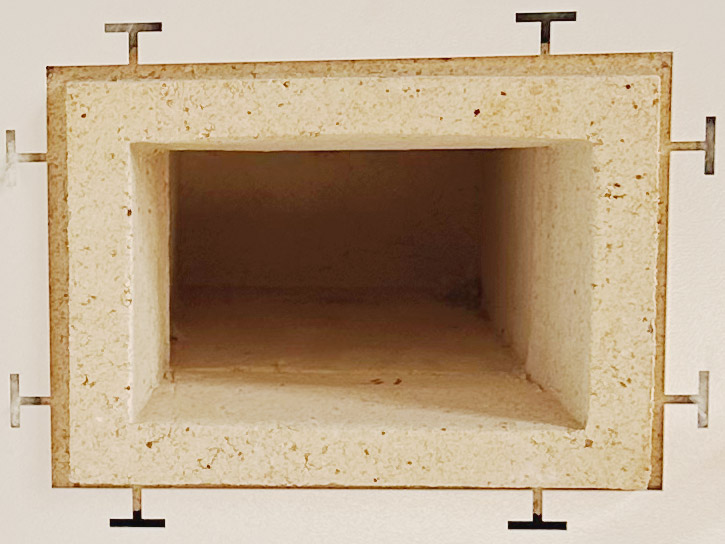

The appearance is beautiful, avoiding the cumbersome installation of customers. The inner furnace lining is a rectangular integral furnace lining made of high aluminum and silicon carbide refractory materials. The spiral heating element made of iron-nickel-chromium-aluminum alloy wire is passed through the wire grooves on the upper, lower, left and right of the inner furnace lining. Heating up and down, left and right.

Sealed structure

The furnace is a sealed structure, and the inner furnace and the furnace shell are built with refractory fiber aluminum silicate wool and diatomaceous earth products as an insulation layer.

Chimney smoke exhaust device

The overall design is reasonable and has a long service life. The furnace door and chimney exhaust device are opened on the left, which is easy to operate. Beautiful shape, sophisticated workmanship, strong and durable, not easy to deform.

Technical parameters of Muffle Furnace

| Model | BZH-2.5-10 (2.5-12) | BZH-4-10 | BZH-5-12 | BZH-8-10 | BZH-10-12 | BZH-12-10 | BZH-12-12 |

| Temperature range | 100~ 1000℃ (1200℃) | 100 ~ 1000℃ | 100 ~ 1200℃ | 100 ~ 1000℃ | 100 ~ 1200℃ | 100 ~ 1000℃ | 100 ~ 1000℃ |

| Volatility | ±2℃ | ±2℃ | ±2℃ | ±2℃ | ±2℃ | ±2℃ | ±2℃ |

| Display accuracy | 1℃ | 1℃ | 1℃ | 1℃ | 1℃ | 1℃ | 1℃ |

| Furnace size | 80*120*200 | 120*200*300 | 160*250*400 | 200*300*500 | |||

| Heating speed | Average ≤10℃/min | ||||||

| Total power | 2.5kw | 4kw | 5kw | 8kw | 10kw | 12kw | 12kw |

| Power supply | 220V, 50Hz | 380V, 50Hz | |||||

Furnace shell material: The outer shell is made of high-quality cold plate, treated with phosphoric acid coating salt, and then sprayed with high temperature plastic. The color is computer gray

Furnace core material: High aluminum inner core is used, which has good wear resistance. The high-temperature furnace heats up and down, left and right

Insulation method: Insulation bricks and insulation cotton

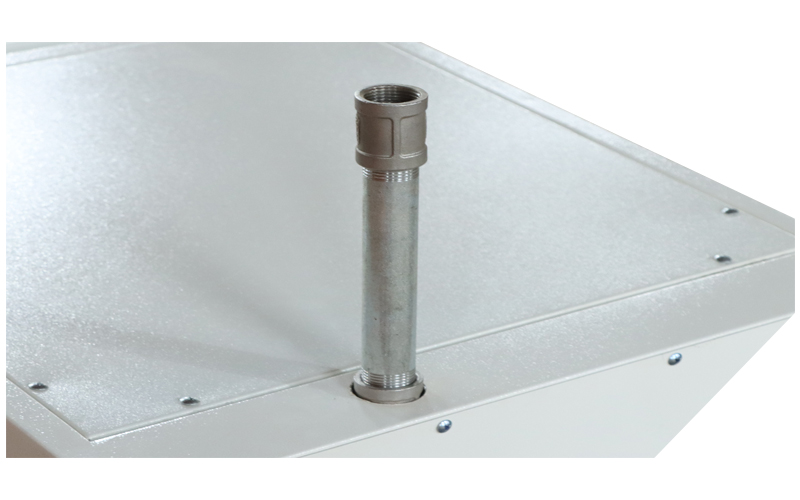

Temperature measuring port: Thermocouple enters from the upper back of the furnace body

Binding post: The heating furnace wire terminal is located at the lower back of the furnace body

Controller: Located below the furnace body, with built-in control system, and compensation wire connected to the furnace body

Heating element: High-temperature resistance wire

Standard packaging: Export Wooden box

Temperature measurement: K-division nickel-chromium-nickel-silicon thermocouple

Control system: PID adjustment, display accuracy 1℃

Electrical equipment: Brand contactor, cooling fan, solid-state relay

Time control: Working time can be set, constant temperature time is reached, automatic shutdown

Over-temperature protection: Built-in secondary over-temperature protection device, double insurance. Over-temperature alarm, over-temperature cut-off

Operation mode: Full-scale adjustable constant temperature, constant operation

Maintain

1. Open the machines everyday periodically.

2. Operated by the specialist.

3. The equipment and accessories must be deposit in the dry environment.

4. After testing the accessories should be added wiping grease rust, and remove the rust great before test.

5. When the test finished, the power should be closed to avoid any accident.