- Home

- >

- News

- >

- Industry News

- >

- Muffle furnace -Ash content detection

Muffle furnace -Ash content detection

Muffle furnace -Ash content detection

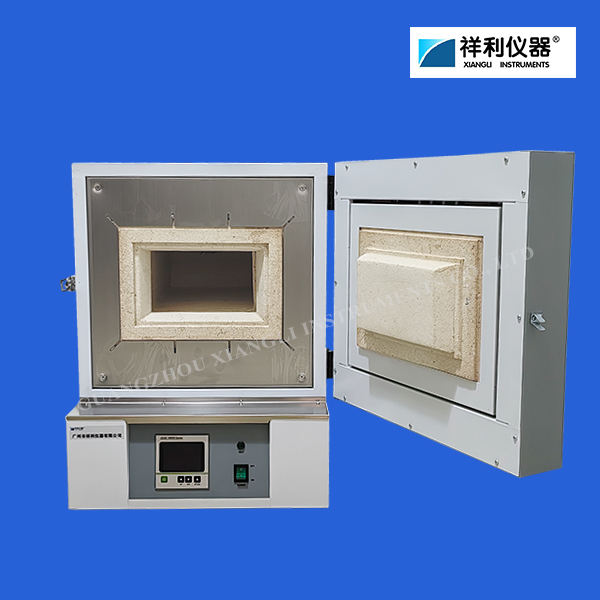

★ Muffle furnace - "high temperature laboratory" for plastic physical property testing.

In the plastic industry, muffle furnaces are suitable for laboratories, industrial and mining enterprises, and scientific research units for element analysis and heating

during heat treatment such as quenching and tempering of general small steel parts.

From scientific research innovation to industrial production, accurate control of plastic physical properties is the lifeline of product quality. Guangzhou Xiangli Instruments'

muffle furnace, with its excellent high-temperature processing capabilities and precise temperature control technology, has become the core tool for plastic physical

property testing, and has escorted the in-depth analysis and quality upgrade of plastic performance.

★ Muffle furnace is the "gold standard" for quantification of plastic components and ash content testing.

Put the plastic sample in the muffle furnace for high-temperature burning, the organic matter is completely decomposed and volatilized, and the residual ash is

precisely weighed, which can quickly and accurately determine the content of inorganic fillers (such as calcium carbonate, talcum powder) and impurities in the

plastic. This data is crucial to controlling the stability of plastic formulas and evaluating the mechanical strength and electrical insulation properties of products.

It is widely used in quality control of products such as pipes and electrical housings.

The muffle furnace uses the power of high temperature to open up a precise path for plastic physical property testing. Whether it is scientific and innovative

material research and development or quality control on the production line, the muffle furnace is your ideal partner for exploring the boundaries of plastic

performance and safeguarding product quality.