- Home

- >

- Products

- >

- Injection Machine

- >

- Testing sample injection molding equipments

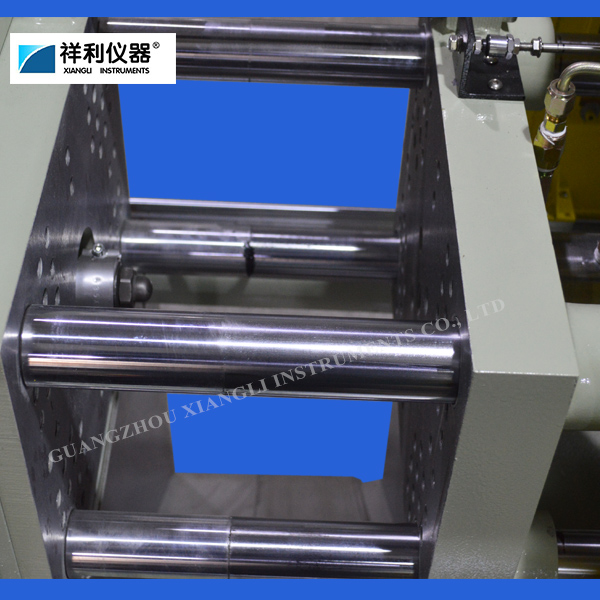

Testing sample injection molding equipments

Brand :XIANGLI

Product origin :China

Delivery time :10 days

Supply capacity :1000

This GZ series injection machine direct-pressure energy-saving small injection molding machine is equipped with a power-saving system. Each movement of the whole machine is fast and smooth. It has good control performance and repeatability. Compared with traditional machines, it has extremely excellent super energy-saving effects (power saving, water saving, fuel saving), bringing you real economic benefits.

Product specification

Thermoplastic or thermoset plastics are made into various shapes of plastic products.

This injection machine is equipped with a PLC programmable computer LCD touch screen. The temperature, time, pressure and flow rate can be set arbitrarily. Multi-stage pressure injection molding is easy to operate, precise in action, and has stable plastic injection molding quality and performance. It is suitable for small sizes of different plastice Forming of parts.

Product advantage

The GZ series injection machine direct-pressure energy-saving small injection molding machine is equipped with a power-saving system. Each movement of the whole machine is fast and smooth. It has good control performance and repeatability. Compared with traditional machines, it has extremely excellent super energy-saving effects (power saving, water saving, fuel saving), bringing you real economic benefits.

Main features

※Energy saving

1. The injection machineis small and exquisite, covers a small area, and saves factory space and electricity;

2. The hydraulic system adopts German BOSCH high-flow, high-response semi-closed loop proportional valve and imported pressure sensor, combined with a specially designed high-rigidity hydraulic circuit to achieve precise semi-closed control. The entire system has high response, low noise, and low energy consumption. features while having extremely high repeatability.

※Precision

1. It adopts new high-speed precision controllers from Japan and Germany, supplemented by independently developed software, and has good human-machine interchangeability;

2. Precise direct-pressure mold clamping structure, multi-stage pressure, speed control and low-pressure protection functions ensure stable and reliable mold clamping and increase the service life of the mold;

3. The parallel injection cylinder has a reasonable structure, compact movement, low energy consumption, and high control accuracy. The injection pressure is precisely controlled by sensor feedback, and the injection position is more accurate. The low-speed, high-torque, short hydraulic motor drives the screw, and the feeding is stable and precise.

※Humanize

1. The injection molding unit has a compact structure and can be adjusted vertically and horizontally;

3. A smaller plasticizing amount can be selected to achieve micro-injection;

4. A variety of specifications are available, which can provide a larger injection volume and meet customer needs to the greatest extent;

According to the characteristics of plastic products, the optimal injection molding process can be flexibly set up to ensure high production quality and low molding cycle of injection molded products, thereby having stronger market competitiveness.

Product parameter

| Name of item | Unit | GZ-20 | |

Injection system | Screw diameter | mm | 22 |

| Theoretical injection capacity | Kg/cm2 | 40 | |

| Injection weight | g/OZ | 40/1.4 | |

| Injection rate | cm2/sec | 57 | |

| Screw stroke | mm | 110 | |

| Injection pressure | Kg/cm2 | 2170 | |

| Screw speed | rpm | 0-215 | |

| Temperature control section | 3+1 | ||

Clamping System | Clamping force | Tons | 20 |

| Open mold trip | mm | 215 | |

| The maximum mold opening distance | mm | 255/315 | |

| Template size | mm | 380*290 | |

| Modular spacing | mm | 250*200 | |

| The smallest mold thickness | mm | 100/40 | |

| Top travel | mm | 35 | |

| Top of the power | Tons | 1.3 | |

Hydraulic power system | Maximum hydraulic pressure | Kg/cm2 | 140 |

| Pump leaf output | L/min | 31 | |

| Action oil | L | 80 | |

| Cooling water consumption | LH | 400—600 | |

| Motor Power | Kw | 4(5HP | |

| Electric capacity | Kw | 2 | |

| Total electricity consumption | Kw | 6 | |

Other | The total weight of the machine | Kg | 1000 |

| Packing weight | Kg | 1200 | |

| Packing size | m | 2.1*0.7*1.5 | |

Machine dimensions | m | 2.02*0.6*1.4 | |

Maintain

1. Open the machines everyday periodically.

2. Operated by the specialist.

3. Testing sample injection molding equipments and accessories must be deposit in the dry environment.

4. After testing the accessories should be added wiping grease rust, and remove the rust great before test.

5. When the test finished, the power should be closed to avoid any accident.

Certificate