- Home

- >

- Products

- >

- Universal Testing Machine

- >

- Universal tensile testing machine

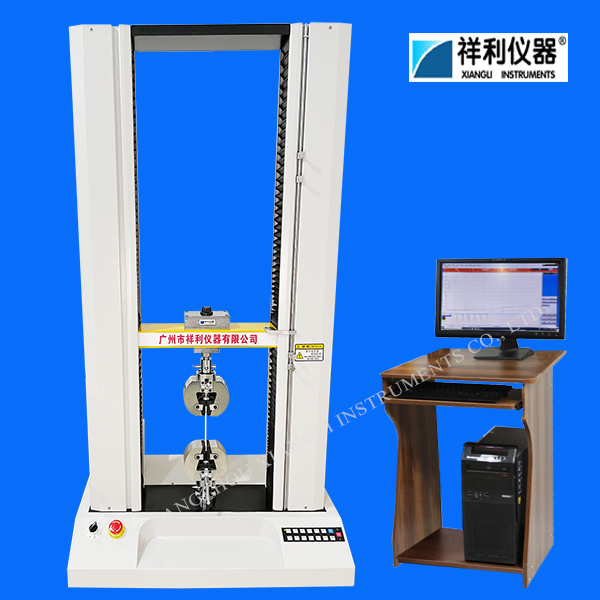

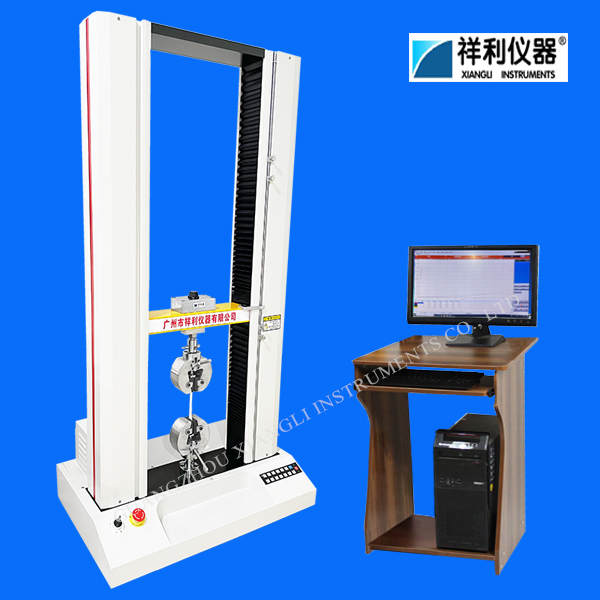

Universal tensile testing machine

Brand :XIANGLI

Product origin :China

Delivery time :10 days

Supply capacity :1000

Universal tensile testing machine is suitable for performing test, compression, bend, shear peel and tear tests of wire plastic, rubber, cable, waterproof, wrapping and textile fibre.

Application

Various mechanical properties tests

This Universal tensile testing machine is mainly used to measure the strength of various materials (rubber, plastic, waterproof materials, textiles, cables and wires, fibers, paper, metal wires, springs, packaging materials, etc.) under tension, compression, bending, shearing, etc.

Mechanical property testing and related physical parameter analysis.

Compact structure, simple operation

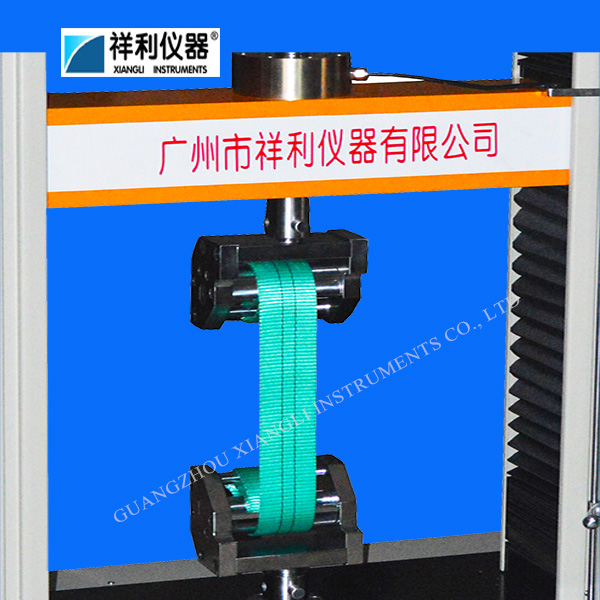

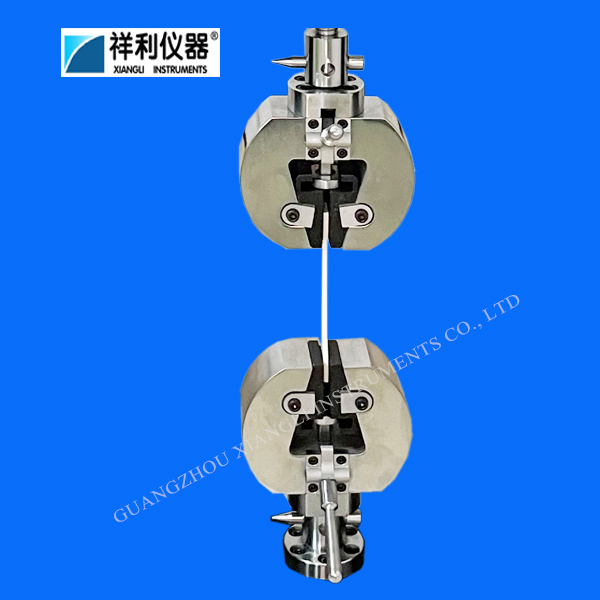

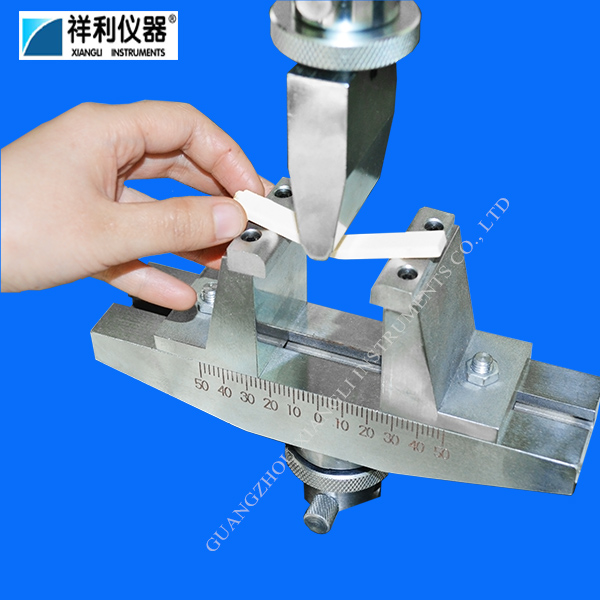

This Universal tensile testing machine equipped with different clamps, it can also be used for tearing, peeling, puncture and other tests. This Universal tensile testing machine has the characteristics of compact structure, simple operation and convenient maintenance.

This Universal tensile testing machineis an ideal mechanical testing and testing equipment for colleges and universities, scientific research institutes, quality inspection departments and related production units. Compliance: GB1040-2006; GB/T9341-2000; GB9647-2003; GB/T14694-93; ISO: 527-1993; ISO: 9969; ASTM: D638-98; ASTM: D790-99; ASTM: D695-96 ; ASTM: D2412

Normal working conditions

1. At room temperature within the range of 10°C to 35°C;

2. Relative humidity is not greater than 80%;

3. Install it horizontally on a stable foundation, with the levelness not greater than 0.2/1000;

4. There is no strong vibration, corrosive medium and strong electromagnetic field around;

5. The power supply voltage fluctuation range must not exceed ±10% of the rated voltage, and the power supply frequency is 50Hz;

6. There is an independent ground wire;

7. There should be a space of no less than 0.7m around the testing machine, and its working environment should be clean and dust-free.

Working principle

The servo controller drives the servo motor to work according to the test parameters set by the control instrument. The motor drives the moving beam to move through the deceleration system and the ball screw pair, and then applies test force to the sample through the clamps installed on the moving beam and the fixed beam, thereby achieve the purpose of the test.

Product parameter

| Type | XLS-10KN | XLS-20KN | XLS-50KN |

|

Max load |

10(KN),1000(Kg) |

20(KN),2000(kg) |

50(KN),5000(kg) |

|

Diameter of the sample |

400(mm) |

400(mm) |

400(mm) |

|

Travel of the cross beam |

Single measure automatically for 1100(mm) |

Single measure automatically for 1100(mm) |

Single measure automatically for 1100(mm) |

|

Sensor power value |

50N-10KN | 50N-20KN | 50N-50KN |

|

Resolving capability |

1/250000 |

||

|

Sensor accuracy |

0.003%F.S./degree |

||

|

Range of testing speed |

0.001-800mm/min(10KN)

0.001-500mm/min(10KN)

|

0.001-800mm/min(20KN)

0.001-500mm/min(10KN)

|

0.001-800mm/min(20KN)

0.001-500mm/min(10KN)

|

|

Return speed |

0.001-800(mm/min) |

0.001-800(mm/min) |

0.001-800(mm/min) |

|

Dimension(L×W×H) |

790×480×1460(mm) |

790×480×1460(mm) |

790×480×1460(mm) |

|

Weight |

115kg |

125kg |

135kg |

|

Load measures accuracy |

When the load measure is 2% to 100% of the sensor load, the accuracy is ±0.5% of the showed load measure. When the load measure is smaller than the sensor load for 2%, the accuracy is 1% of the showed load measure.

R..O:±0.5% or±1%

|

||

Main features

The control system of this Universal tensile testing machine is based on a single-chip microcomputer and has a touch screen and control keyboard. Electronic universal tensile testing machine can operate independently and display the load value, displacement value and beam movement speed. In addition, the control system circuit of this Electronic universal tensile testing machine uses E2PROM as the storage carrier of the configuration. The test parameters can be set or modified through the touch screen and ensure that the set test parameters will not be lost when the machine is not turned on for a long time.

Equipped with standard RS232c serial communication interface. When using microcomputer control, it is equipped with multi-language user interface software to automatically collect and process data, and can print test reports and load-displacement curves (stress-strain curves). During the test operation, the load value, displacement value, beam moving speed and load-displacement curve (stress-strain curve) are dynamically displayed. Electronic universal tensile testing machine can be calibrated by software and has overload protection function.

Maintain

1. Open the machines everyday periodically.

2. Operated by the specialist.

3. Universal tensile testing machine and accessories must be deposit in the dry environment.

4. After testing the accessories should be added wiping grease rust, and remove the rust great before test.

5. When the test finished, the power should be closed to avoid any accident.

Certificate